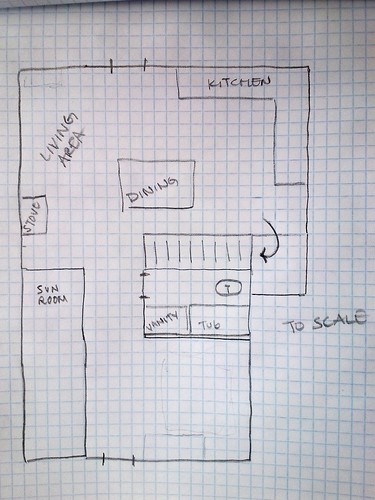

The two major renovation projects on our list are relocating the stairs and the bathroom. Chandler tackled building the new bathroom walls and completely redoing all of the plumbing. That took up pretty much all of his time, so, I was in charge of the stairs. If you have never built stairs before, let me start by stating, they are complicated.

The stair case I am building is L-shaped, meaning there is a landing in the middle where the stairs take a 90° turn. While this style will fit our house better, it makes the construction a little more complicated. The first step (ha ha) is to build the landing, which must be a specific height. The complication arises because our floors are really uneven. So, first floor to second floor height is different where the stairs will begin, end and the location of the landing. After much deliberating and repeated measurements, I settled on a final height and began building.

Next came the stringers. I had done all the calculations for the rise and run and could only hope it worked out. After laying our my measurements on the 2×12, it was time to cut.

Surprisingly, my stringer fit perfectly!

At this point, we could get more than half way up to the next floor, but I couldn’t continue until we opened the ceiling. This felt like a big step, only because it would be a lot of work if we changed our minds.